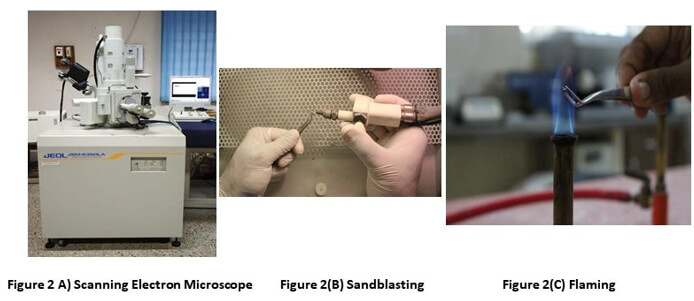

Aim &Objective: The purpose of the study is to compare the shear bond strength of recycled orthodontic bracket by using air abrasion and flaming technique. Materials and Methods: Fifty-one premolar teeth extracted for orthodontic purpose were selected for this study. Pre- adjusted edgewise premolar brackets of “0.022” inch slot (3M Gemini) were bonded. And the samples were categorized into three groups of 17 samples per group. Group I consist of fresh brackets (Control group) in which no recycling methods where carried out. Group II consist of brackets recycled by air abrasion technique with aluminum oxide (110 micrometer) abrasion. Group III consist of brackets recycled by direct flaming technique. Teeth in each group were mounted vertically on a dental acrylic block. Debonding and shear bond strength was carried out by the use of a universal testing machine. The groups were compared using ANOVA and Post HOC test. A Scanning Electron Microscope (SEM) was used to assess the changes during the air abrasion and flaming technique. Result: There was a statistically significant difference in shear bond strength between the air abrasion bracket with flaming bracket. (P < 0.05). And also, the SEM showed there was an increase in the surface area of the air abrasion bracket base when compared to flaming group with an increase in the retentive areas. Conclusion: It was noted that surface roughness was directly correlated to the bond strength. Shear bond strength was seen to be more on air abrasion group as compared to the flaming group, so air abrasion method is one of the efficient methods for recycling the debonded orthodontic brackets which is also cost effective.

Key words: Flaming, Rebonding, air abrasion, Shear bond strength, Scanning Electron Microscope (SEM).

Objetivo: El propósito del estudio es comparar la fuerza de unión a cizallamiento del bracket de ortodoncia reciclado mediante el uso de la abrasión con aire y la técnica de flameado con fuego. Materiales y métodos: Cincuenta y un dientes premolares extraídos con propósito de ortodoncia fueron seleccionados para este estudio. Los brackets premolares preajustados de ranura de "0.022" pulgadas (3M Gemini) fueron cementados Y las muestras se clasificaron en tres grupos de 17 muestras por grupo. El Grupo I consiste en brackets nuevos (grupo de control) en los que no se llevan a cabo métodos de reciclaje. El Grupo II consiste en brackets reciclados por técnica de abrasión de aire con óxido de aluminio (110 micrómetros). El Grupo III consiste en brackets reciclados por técnica de flameado directo. Los dientes de cada grupo se montaban verticalmente en un bloque de acrílico dental. La resistencia a la unión de descementado y cizallamiento se llevó a cabo mediante el uso de una máquina de prueba universal. Los grupos se compararon utilizando la prueba ANOVA y Post HOC. Se utilizó un microscopio electrónico de barrido (SEM) para evaluar los cambios durante la técnica de abrasión y flameado. Resultado: Hubo una diferencia estadísticamente significativa en la resistencia de la unión de cizallamiento entre el bracket de abrasión con aire con el bracket flameado. (P < 0,05). Y también, el SEM mostró que hubo un aumento en la superficie de la base del bracket tratado por abrasión con aire en comparación con el grupo tratado con fuego con un aumento en las áreas retentivas. Conclusión: Se observó que la rugosidad de la superficie estaba directamente correlacionada con la fuerza de unión. Se vio que la resistencia a la unión cortante es más en el grupo de abrasión del aire en comparación con el grupo flameado, por lo que el método de abrasión del aire es uno de los métodos eficientes para reciclar los brackets de ortodoncia despegados siendo también rentable.

Palabras clave: flameado, Recementado, abrasión del aire, fuerza de unión cortante, microscopio electrónico de barrido (SEM).

The biggest challenge an Orthodontist faces in his/her routine clinical practice is debonding of the brackets during the routine orthodontic treatment which is usually troublesome for the clinician as well as for the patient1. Bond failure of orthodontic brackets is during the orthodontic treatment which may be due to failure or negligence to maintain the manufacturer’s instructions which includes proper cleaning of tooth surface prior to application of etchant, followed by proper etching, good isolation of tooth surface from blood and saliva, and application of the bonding agent and attachment of the bracket to tooth surface followed by curing. If any negligence happens during this procedures or recontamination of the tooth surface by saliva or blood etc. after etching can affect the bond strength. Clinical studies have shown that when bond failure occurs in 5% to 7% of patients, most of the orthodontic practitioners replace the dislodged orthodontic brackets with a set of new brackets, which increases the treatment costs. Recycling and Rebonding the dislodged bracket can minimize the treatment costs and eliminate the need and use of new brackets2.

Rebonding is a clinical procedure in which the debonded or dislodged orthodontic brackets are subjected to various commercial conditioning treatments whereby the bracket base area is cleaned and the remnants adhesive are removed. This procedure causes macro and microscopic alterations in the structure of bonding surface (mesh), and a new surface area is created for rebonding of the bracket to the tooth surface2.The bond strength of rebonded brackets is very important to ensure the success of treatment.

There are variety of commercial rebonding methods available, all of which are impractical chair side. The two main commercially available methods for rebonding orthodontic brackets includes using thermal or chemical method to remove the adhesive from the base of the bracket. The first method relying on heat application. The second method employs chemical solvents3.The disadvantages of these commercial recycling methods, leads to a degree of metal loss in certain areas of the bracket and a reduction in the diameter of the mesh strand4. In addition, commercially rebonded brackets are more prone to corrosion, particularly brackets made from type-304 (AISI) stainless steel5.

Various procedures employed to facilitate rebonding effectively and safe procedure of resin removal after debonding. This resulted in the innovation of various chairside instruments and technical procedures. These include the use of tungsten carbide burs (TCA), diamond burs, air abrasion / sandblasting, soflex disc. and flaming methods (Buchman Method), which consists of application of direct flame to the bracket base to burn the composite off, followed by electro polishing.1 The major advantage of this type of chairside recycling and rebonding technique is economic savings and less chances of distortion, which could be as high as 90%, since a single bracket can be recycled and reused as many as five times on a same patient6. Other advantages which includes a smoother, and more corrosion-resistant bracket after electro polishing and sterility as a result of the temperatures employed in these recycling procedures. Disadvantages may include loss of identification markings but latest brackets are laser numeric marks2.

Regan reported a 41% decrease in the bond strength of flamed brackets, which was equal to the decrease seen with brackets that had been roughened with only a green stone6. Sonis reported that there is no significant difference in the shear bond strength of new and sandblasted brackets7.

MBT brackets 0.022-inch slot (3M Gemini), Etchant (37% Phosphoric Acid), Bonding Agent (5th generation), Aluminum oxide (110 micrometer), Burner for flaming, freshly extracted premolars, bracket holder, Saline solution Debonding pliers, Universal testing machine, Scanning Electron Microscope.

An in-vitro study was conducted in the Department of Orthodontics and Dentofacial Orthopedics, Ethical clearance was obtained from the ethical committee. 51 premolar teeth that where extracted for orthodontic purpose were selected for this study. Teeth were thoroughly cleaned to remove any soft tissue debris and blood and where stored immediately in saline solution to prevent any dehydration until the study is conducted. Pre- adjusted edgewise premolar brackets of “0.022” inch slot (3M Gemini) were bonded to the teeth.

The samples were categorized into three groups of 17 samples per group

The tooth surfaces to be bonded were cleaned, rinsed, and thoroughly air dried. Etchant (3M Scotch bond) was applied to the tooth for 15 seconds, rinsed for 15 seconds, and dried for 2 seconds. A thin coat of primer (3M Transbond XT light-cured adhesive primer) was then applied, followed by adhesive to the bracket base of new brackets (control group), and light-cured for 10 seconds

Teeth in each group where mounted vertically on a dental acrylic block. The dental acrylic base was filled up to the level of normal alveolar bone level surrounding the individual premolar tooth. Tooth are aligned in such a way that their facial surfaces were perpendicular with the bottom of the mold; i.e., each tooth is oriented in such a way that their labial surface is parallel to the direction of force during the shear bond strength testing.

Inclusion Criteria:

Exclusion Criteria:

Initial debonding procedure were performed by using an orthodontic debonding pliers in such a way that the brackets were held mesio-distally and a peeling type of force was exerted to debond the bracket from the tooth surface for the two groups (Group II, Group III). In Control group (Group I) the bonded brackets were attached to tooth surface until shear testing i.e., no debonding procedure was done.

To remove the resin layer from the debonded bracket base prior to rebonding two different chair side recycling methods were performed on the experiment groups.

Group I: Control group

There are no recycling procedures were done on to the control group.

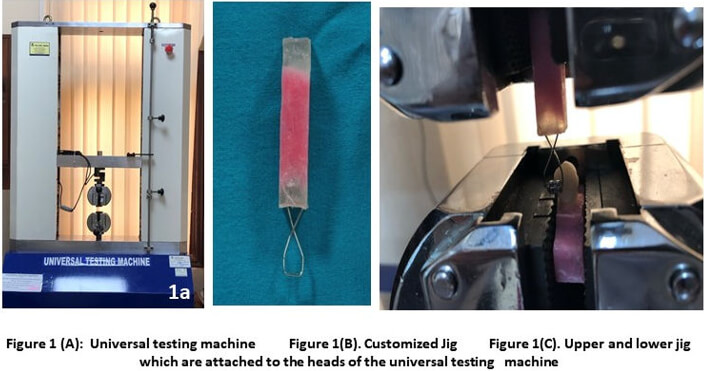

Group II: Air abrasion/ Sandblasting with aluminum oxide (110 micrometer)

The initial debonded 17 brackets are recycled by removing the composite from the base of the brackets by using air abrasion technique. In which aluminum oxide particles of size 110 micrometer were used. These aluminum oxide particles were sprayed to the base of the brackets from the nozzle of the air abrasion machine. Each bracket base was air abrasion for 20 to 40 seconds under 80 ps pressure. The composite was removed until the base of the bracket became glossy without any macroscopically visible composite on the bracket mesh under the dental lamp’s light. (Figure 2B)

Group III: Direct flaming (600-8000C)

The initial debonded 17 brackets were recycled by removing the composite from the base of the brackets by using flaming technique by the help of a Blow torch or a Bunsen burner. The flame tip of a Bunsen burner was pointed at the bracket base, by which the bonding agent ignite and burn off. (Figure 2 C)

The adhesive was removed from the bracket base till it became glossy without any macroscopically visible adhesive for Groups II & III.

Rebonding of the recycled brackets were done using standard bonding procedures. After the brackets were reconditioned, each were bonded to the enamel surfaces that had been prepared for rebonding, using same method as for new brackets which includes acid etching with 37% phosphoric acid gel (3M Scotch Bond) for 20-30 seconds followed by thorough washing and air drying for 20 seconds. The bonding agent (3M Unitek Transbond XT) was applied on the tooth and the brackets base. M.B.T Pre–adjusted edge wise premolar brackets of “0.022” inch (3M Gemini) was placed on the tooth. All samples were light cured with LED curing light at 1200 mW/cm2 for 20s. Before light curing the adhesive, the brackets were pressed on the tooth to remove the excessive adhesive or Flash which is removed with the help of a sharp probe.

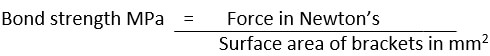

The shear bond strength of recycle orthodontic brackets were performed by the use of a universal testing machine (Figure1A). The tooth specimens were mounted to the acrylic block which were secured to the fixed lower grip of the universal testing machine. To maintain a consistent debonding force to the bracket, a custom-made jig(Figure 1B) was fixed to the upper grip (moveable head) connected to the load cell. (Figure 1C) The jig was customized in such a way that it will engage to horizontal slot of the “0.022” inch bracket. The jig was designed with a “0.019 x 0.025” inch stainless steel wire. The wire is taken and was bend in such a way that the part of the wire entering to the “0.022” inch slot of the bracket was tightly in contact with the bracket slot. The length of the wire is equal to the mesio distal width of the bracket slot and the wire is given a vertical bend upwards so that it will get embedded in the acrylic.

The speed of the crosshead is 1 mm/min was programmed. The computer software is used to recorded the force that is required for debond the bracket from the tooth surface in Newton’s. The shear bond strength was calculated in MPa using the formula.

The surface area of the bracket was 9.80 mm2 given by the manufacturer company.

A customized jig was suspended from crosshead of universal testing machine. A Gingivo-occlusal load was applied to the brackets, producing shear forces at the bracket-tooth interface for all the three groups. A computer, electronically connected with the test machine, records the result of each test.

A scanning electron microscope (SEM) (Figure 2A) was used to compare the surface characteristics of the new and rebonded bracket bases. (Figure 3) Each specimen was prepared for SEM by sputtering with gold palladium in a Polaron E5100 sputter-coating unit. The bases of the brackets were then examined under an SEM (JEOL ISM 6380 A) operated at 10 KV at different 25× and 150×.

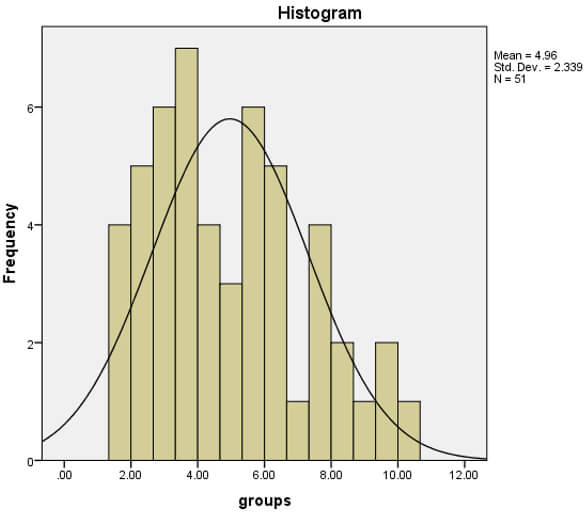

One-way ANOVA followed by Tukey’s HSD test were done or corresponding non-parametric test to compare the groups with SPSS software (IBM SPSS Statistics for Windows, Version 23.0. Armonk, NY: IBM Corp).). Statistical analysis was carried out using the ANOVA tests and Post HOC Test and normality distribution curve.

In this study the shear bond strength of recycled orthodontic brackets was evaluated and compared by using two different chair side recycling techniques such as air abrasion and flaming technique.

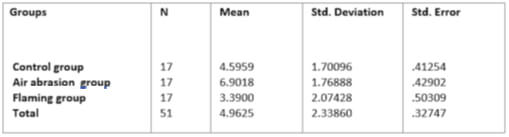

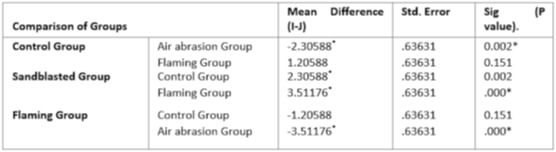

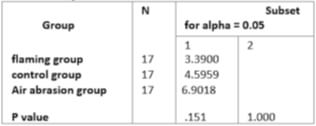

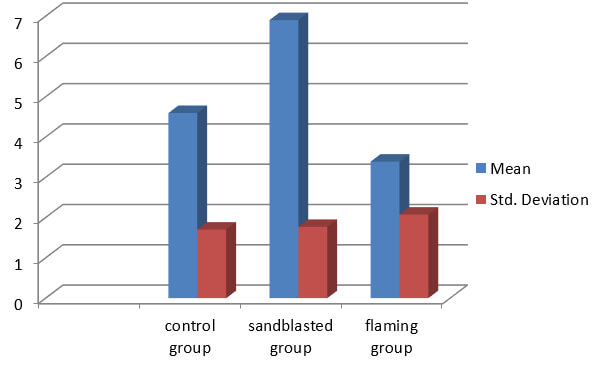

All statistical analysis was carried out using the ANOVA tests and Post HOC Test with SPSS software (IBM SPSS Statistics for Windows, Version 23.0. Armonk, NY: IBM Corp). One-way ANOVA followed by Tukey’s HSD test and normality distribution curve (Graph2) were done to evaluate and compare the shear bond strength. P < 0.05 were considered statistically significant. The statistical analysis shows that sandblasted group shows better shear bond strength (p = 0.002) than flaming group (p = 0.151) (Table 1), (Table 2), (Table 3). The mean and standard deviations of shear bond strength of individual groups were also compared. (Graph 1). The data follows a normal distribution (Graph 2)

Abbreviation

Bond failures that happen during the orthodontic treatment procedure is relatively unavoidable and unenviable. Hence, this study was put forward to evaluate the shear bond strength of rebonded orthodontic brackets using two different chair side composite removal techniques.

The main goal behind the rebonding process is to completely remove the orthodontic bonding material from the base of the bracket without damaging or weakening the delicate foil mesh or distorting the dimension of the orthodontic bracket slot. Many literatures show that significant differences exist between bond strengths for different tooth type. Thus, studies that are related to bond strength on enamel surface should ideally take these factors into consideration and use only one type of tooth or equal number of different tooth types. Therefore, in this study, maxillary first premolars were taken into consideration due to their relative availability when compare to other tooth because they were frequently extracted for therapeutic orthodontic treatment purpose. In this study, all the tooth samples were store in distilled water to prevent dehydration to the tooth specimens during the study.

It has been noted that a good bonding between the base of bracket and enamel surface is required for withstanding stresses and shearing forces that are constantly acting to the brackets-tooth interface which are created during mastication so that the brackets were held in position during the orthodontic treatment. The factors that are responsible for debonding the orthodontic brackets during the treatment from the tooth surface includes improper bonding technique, lack of mechanical retention of the bracket base, and heavy masticatory forces. After the advent of direct bonding technique in the 1970s, various methods have been evolved for recycling and rebonding the accidentally dislodged orthodontic brackets to the tooth surface so that they can be recycled and reused thereby reducing the cost per case.

Recycling the debonded bracket by removal of residual adhesives that are retained to the bracket bases can be performed commercially. Two various methods which are commercially available which includes (1) Application of heat for adhesive removal by burning the composite from the bracket base, followed by electrolytic polishing for removal of oxide layer and (2) use of various chemical solvents for dissolving the adhesive which can be combined with frequency vibrations, and electrochemical polishing. These commercial methods are time consuming and are not available everywhere. However, other methods were employed that can be performed chair-side for recycling and rebonding of debonded brackets have been evolved. The commonly available chair side techniques include air abrasion / sandblasting by aluminum oxide particles, direct flaming followed by electro polishing, or grinding with green stone bur. These methods are less time consuming and can be carried out in the dental office with minimal cost.

The disadvantages of these techniques include distortion of brackets, loss of physical properties. Improper use of green stone and burs for a prolonged period of time causes loss of mesh from the bracket base resulting in debonding and there is a change in the colour, distortion and change in the physical properties of the both stainless-steel and ceramic brackets which look unaesthetic for the patients.

Many factors contribute for bond strength of the orthodontic bracket such as tooth type, materials used for bonding procedure, proper isolation and proper bonding technique. One of the important factors which determine the bond strength is the amount of horizontal pressure which is applied during the placement of the bracket to the tooth surface, for the removal of excessive adhesive flash but most of the studies regarding the bond strength have not taken this factor into consideration ,and after performing the air abrasion technique it is noted that there is an increase in the surface area This air abrasion procedure causes macro and microscopic alterations in the structure of bonding surface (mesh), and a new surface area is created for rebonding of the bracket to the tooth surface as shown in the Scanning electron microscopic examination(SEM).

In this study, the adhesives are removed from the bracket base by employing air abrasion and flaming technique. The air abrasion technique were performed by using aluminum oxide particles of 110μm. Various studies have confirmed that sandblasting with 110 μm aluminum oxide particles is an effective method for removal of residual adhesive from the bracket base without compromising the bond strength. The flaming technique was employed by the help of Bunsen burner were the residual adhesives get ignite and burned off.

These procedures are less time consuming and cost effective that facilitates the re-use of accidentally debonded orthodontic brackets and attachments.

A universal test machine was used for the find out the shear bond strength in which Gingivo-Occlusal vertical shearing force was applied to the occlusal sides of bracket with a crosshead speed of 1 mm/min. The maximum amount of load necessary to debond or initiate the bond fracture was recorded in Newton (N) and was used to calculate the shear bond strength in MPa units.

One-way ANOVA followed by Tukey’s HSD test were done to evaluate and compare the shear bond strength. P < 0.05 were considered statistically significant. The results of this present study show favorable shear bond strength for air abrasion group than flaming groups with statistically significant results in which the air abrasion group shows p valve of 0.002 when compared to flaming group (p value 0.151) It is also noted that when compared to control group the air abrasion group shows statistically significant shear bond strength which implicates that there is an increase in the surface area of air abrasion group when compared to control group. (Table 1), (Table 2).

The mean bond strength of the air abrasion brackets was 6.90 MPa, direct flaming brackets were 3.39 MPa. A similar study conducted by Sachdeva K et al. attained the shear bond strength which was comparable to clinically acceptable bond strength of 6-8 MPa.9

MacColl8 observed that there is a reduction in bond strength with the reduction of bracket base surface area from 6.82 to 2.38 mm2. In this study, all the brackets were taken of the same type. The brackets used were maxillary first premolar metal brackets of “0.022” inch slot and the bracket surface area were determined to be 9.80 mm.2

The study points out the best chair side method which can be employed for recycling the accidentally debonded bracket during the orthodontic treatment. In case of custom-made brackets such as INCOGNITO and various lingual technique, and cases of self-ligating brackets like DAMON and other esthetic bracket these recycling and rebonding methods can be employed so that the treatment can be cost effective and they are less time consuming.

The limitations of this study are

The conclusions that can be drawn from this study which includes:

Therefore, our study recommends that air abrasion can be used as a preferred method of reconditioning the accidentally debonded orthodontic brackets to achieve an optimal bond strength.

Conflict of interest

None declared

Declarations

Ethics Approval:

The ethical approval was obtained from the ethical committee

Consent for publication: this manuscript has all the consent for publication

Funding

Not funded

Availability of data and materials

Data are not shared with out the consent from the author

Authors contributions: all the authors actively participated during the study

Acknowledgement: Not applicable